Simply to make manipulation attempts more difficult on a technical level, as laid out in the supplement to EN 1088 for example, only appears to solve the problem. For if there is enough pressure, a “solution” will be found. It's more important to eliminate the reason for manipulation. What's needed is not excessive functionality (even in terms of safety technology), but user friendliness. If there's any doubt as to whether the safety concept is adequate, it's recommend that you seek expert advice from the relevant employer's liability insurance association or from the safety component manufacturer.

Guards use physical barriers to stop people and hazardous situations coinciding in time and space. Their essential design requirements are stated in EN 953 and EN 1088. Safety-related and ergonomic aspects must be taken into account alongside questions regarding the choice of materials and consideration of mechanical aspects such as stability. These factors are decisive, not just in terms of the quality of the guard function but also in determining whether the safeguards, designed and constructed at considerable expense, will be used

willingly by employees or be defeated and even manipulated.

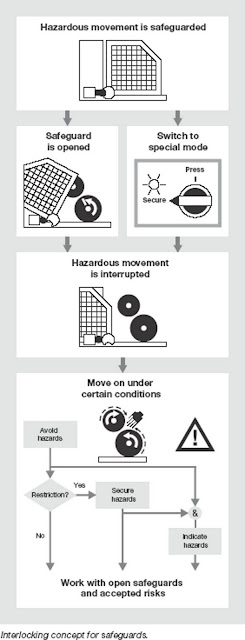

Experience shows that despite all the protestations, almost every safeguard has to be removed or opened at some point over the course of time. When safeguards are opened, it's fundamentally important that hazards are avoided where possible and that employees are protected from danger. The reason for opening, the frequency of opening and the actual risk involved in carrying out activities behind open safeguards (see the following illustrations) will determine the procedures used to attach and monitor safeguards.

Experience shows that despite all the protestations, almost every safeguard has to be removed or opened at some point over the course of time. When safeguards are opened, it's fundamentally important that hazards are avoided where possible and that employees are protected from danger. The reason for opening, the frequency of opening and the actual risk involved in carrying out activities behind open safeguards (see the following illustrations) will determine the procedures used to attach and monitor safeguards.Where safeguards are opened as a condition of operation or more frequently (for example: at least once per shift), this must be possible without using tools. Where there are hazardous situations, use of an interlock or guard locking device must be guaranteed. Further protective measures must be adjusted to suit the resulting risk and the drive/technological conditions, to ensure that the activities

which need to be carried out while the safeguards are open can be performed at an acceptable level of risk. This procedure conforms to the EC Machinery Directive. It allows work to be carried out while the safeguards are open as a special operating mode and gives this practice a legal basis.

Just some final words in conclusion for all designers: Designing interlocks so that absolutely no movement of the machine or subsections is possible once the safeguard has been opened actually encourages the type of conduct which is contrary to safety and, ultimately, leads to accidents. Nevertheless it is the causes you have to combat, not the people. If a machine does not operate as intended, users will feel they have no choice but to intervene. In all probability, the machine will “reciprocate” some time with an accident. Which is not actually what is was designed to do!